Products

Direct

Part Marking Handheld

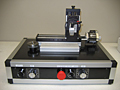

Marking Systems Single Axis Motion

Marking Multi-Axis Motion

Marking Rotary Motion

Marking Marking

Accessories Custom Engineered

Part Marking Systems Custom Engineered

Part Marking Capabilities Custom Engineered

Part Marking Portfolio Part Marking Services Part Marking

Capabilities Part Marking

Portfolio What's New JETMARK II DUAL

POSITION TRAVERSER Documents AS9100D Purchasing Terms & Conditions AS9100D Certificate Quality Policy

Part Marking Handheld

Marking Systems Single Axis Motion

Marking Multi-Axis Motion

Marking Rotary Motion

Marking Marking

Accessories Custom Engineered

Part Marking Systems Custom Engineered

Part Marking Capabilities Custom Engineered

Part Marking Portfolio Part Marking Services Part Marking

Capabilities Part Marking

Portfolio What's New JETMARK II DUAL

POSITION TRAVERSER Documents AS9100D Purchasing Terms & Conditions AS9100D Certificate Quality Policy