Products

Direct

Part Marking Handheld

Marking Systems Single Axis Motion

Marking Multi-Axis Motion

Marking Rotary Motion

Marking Marking

Accessories Custom Engineered

Part Marking Systems Custom Engineered

Part Marking Capabilities Custom Engineered

Part Marking Portfolio Part Marking Services Part Marking

Capabilities Part Marking

Portfolio What's New JETMARK II DUAL

POSITION TRAVERSER Documents AS9100D Purchasing Terms & Conditions AS9100D Certificate Quality Policy

Part Marking Handheld

Marking Systems Single Axis Motion

Marking Multi-Axis Motion

Marking Rotary Motion

Marking Marking

Accessories Custom Engineered

Part Marking Systems Custom Engineered

Part Marking Capabilities Custom Engineered

Part Marking Portfolio Part Marking Services Part Marking

Capabilities Part Marking

Portfolio What's New JETMARK II DUAL

POSITION TRAVERSER Documents AS9100D Purchasing Terms & Conditions AS9100D Certificate Quality Policy

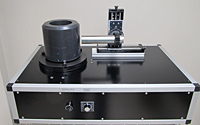

ECM-500 HD Heavy Duty Rotating Marker

Rotary Motion Marking

The ECM-500 HD system provides a geared rotating spindle to mark around the circumference of large bulky products. Cylindrical products such couplings or fittings are set on the spindle tooling and rotated while the inkjet printer is triggered. Multiple options for spindle tooling are available or the customer may provide their own. Print head mounting can be done with fixed positioning, micro-slide adjustment or motor controlled adjustment. Rotation speed can be manual or tied to radius parameters. Full position and speed control for a family of products with bar code recall can be set up with our touch-screen PC and motorized slide options.

Item # |

Item Name |

Description |

Features |

Overall Length |

Overall Width |

Overall Height |

Power |

Standard Hardware |

Quantity |

|---|---|---|---|---|---|---|---|---|---|

| ECM-500 HD /Asset/ECM-500HD.jpg | N/A Heavy Duty Rotating Marker | N/A The ECM-500 HD system provides a geared rotating spindle to mark around the circumference of large bulky products. Cylindrical products such couplings or fittings are set on the spindle tooling and rotated while the inkjet printer is triggered. Multiple options for spindle tooling are available or the customer may provide their own. Print head mounting can be done with fixed positioning, micro-slide adjustment or motor controlled adjustment. Rotation speed can be manual or tied to radius parameters. Full position and speed control for a family of products with bar code recall can be set up with our touch-screen PC and motorized slide options. |

Features

N/A

|

Overall Length N/A 24 in | Overall Width N/A 18 in | Overall Height N/A 8 in | Power N/A 120 VAC 2 Amps | Standard Hardware N/A Foot switch included Printer trigger cable included Tool plate included - attachments optional |